SMART FACTORY

It is a factory that enables to produce goods with the highest quality at the minimum cost and time by combining all processes of the manufacturing process with IT technology centering on data.

The optimized solution for smart factory is becoming essential rather than optional

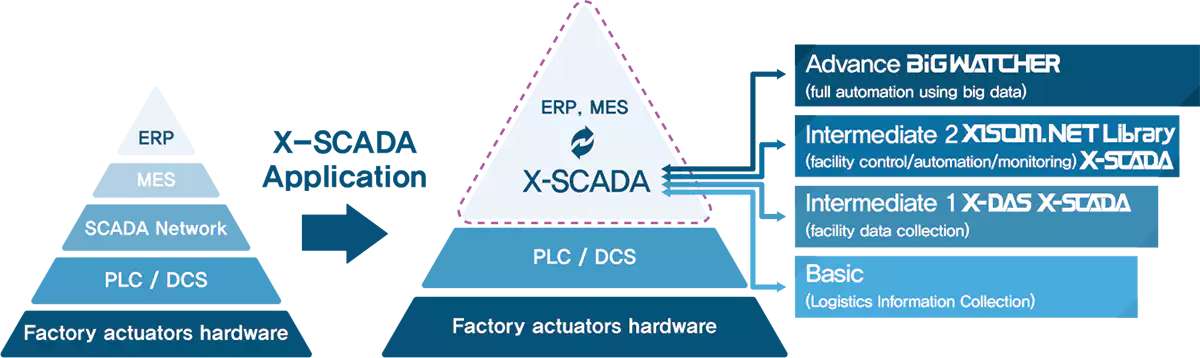

Globally, smart factory is becoming a necessity, not an option. Smart Factory can monitor process data and equipment in real time by incorporating ICT technology into production processes such as design, development, manufacturing and distribution, and improve product quality as well as productivity within the factory through the collected data. XISOM provides the customized solutions optimized for Level 1 (inspection) to Level 5 (autonomous operation) for users and sites to cover all levels.

Smart Factory Level Definition

| Level | Standard | IoT Target | Characteristic | Condition | Main Tool | |

Advance |

Level 5 |

Auto operation |

Workers, facilities, materials, operating conditions + environment |

Customized |

Autonomous progress from monitoring to control and optimization |

AI, AR, VR, CPS etc |

Intermediate2 |

Level 4 |

Optimization |

Workers, equipment, self-cultivation, operating conditions |

Optimized |

Proactive response through process operation simulation |

Sensor controller optimization tool |

Intermediate1 |

Level 3 |

Control |

Workers, equipment, and materials |

Analysed |

Controllable by analyzing collected information |

Sensor + Analysis Tool |

Basic |

Level 2 |

Monitoring |

Workers, equipment, and materials |

Measured |

Real-time monitoring of production information is possible |

sensor |

Level 1 |

Check |

material |

Identified |

Partial standardization and data management |

Barcode rfid |

Concept

Example

Site Application

LOTTE CHILSUNG BEVERAGE

- Digital Transformation Infra standardization

- Data monitoring in the integrated control center (ICC)

- Big data collection in factories for smart factory implementation

POSCO CHEMTECH

- Smart HMI using multi-touch function

- Real-time equipment status data collection/monitoring and alarm management

LS-Nikko

- Integrated web monitoring of real-time equipment status linked with MES

- Real-time data information visualization and monitoring

SK INNOVATION

- Data collection, monitoring and alarm management of each equipment status in a real time

- Automatic collection of data in a certain period according to user setting and calculation formula

- Data visualization through various charts and reports

POSCO ICT

- Heat Treatment Control 3D HMI Platform

- Visible factory implementation and real-time data collection and monitoring

MIREAN

- Monitoring and monitoring of all facilities and processes

- Temperature/humidity monitoring for optimal environmental configuration for the product

- Intuitive on-site management through data

SHINSHIN

- Integration Center construction

- ata monitoring and collection of all facilities

- Visible factory implementation and real-time data management for each facility

OULLIM DESIGN

- Facility control/data collection/monitoring

- Various DB interworking

- Intermediate 1 completion and Intermediate 2 (to be upgraded)

KSC

- Facility control/data collection/monitoring

- Various DB interworking

- Intermediate 1

HEPHZIBAH

- Facility control/data collection/monitoring

- Various DB interworking

- Intermediate 2 (to be upgraded)

KODENSHI

- Facility control/data collection/monitoring

- Various DB interworking

- Medium 2 (to be upgraded)

SAUBER

- Facility control/data collection/monitoring

- Various DB interworking

- WMS Application

SEWANG

- Textile industry standardization smart factory establishment (in progress)

- 3D HMI Platform in the factory

- Control/data collection/monitoring/management of various facilities

BYOKGIN BIO

- Textile industry standardization smart factory establishment (in progress)

- 3D HMI Platform in the factory

- Control/data collection/monitoring/management of various facilities

DAWON ELECTRONICS

- Facility control/data collection/monitoring

- Intermediate 1

Rejection of unauthorized collection of e-mail addresses

This website prohibits unauthorized collection of posted e-mail addresses using e-mail collection programs or other technical devices. Violation of this may be punished by the Act on Promotion of Information and Communication Network Utilization and Information Protection, etc.

arrow_drop_down

arrow_drop_down

EN

EN

JP

JP

.jpg)

.jpg)