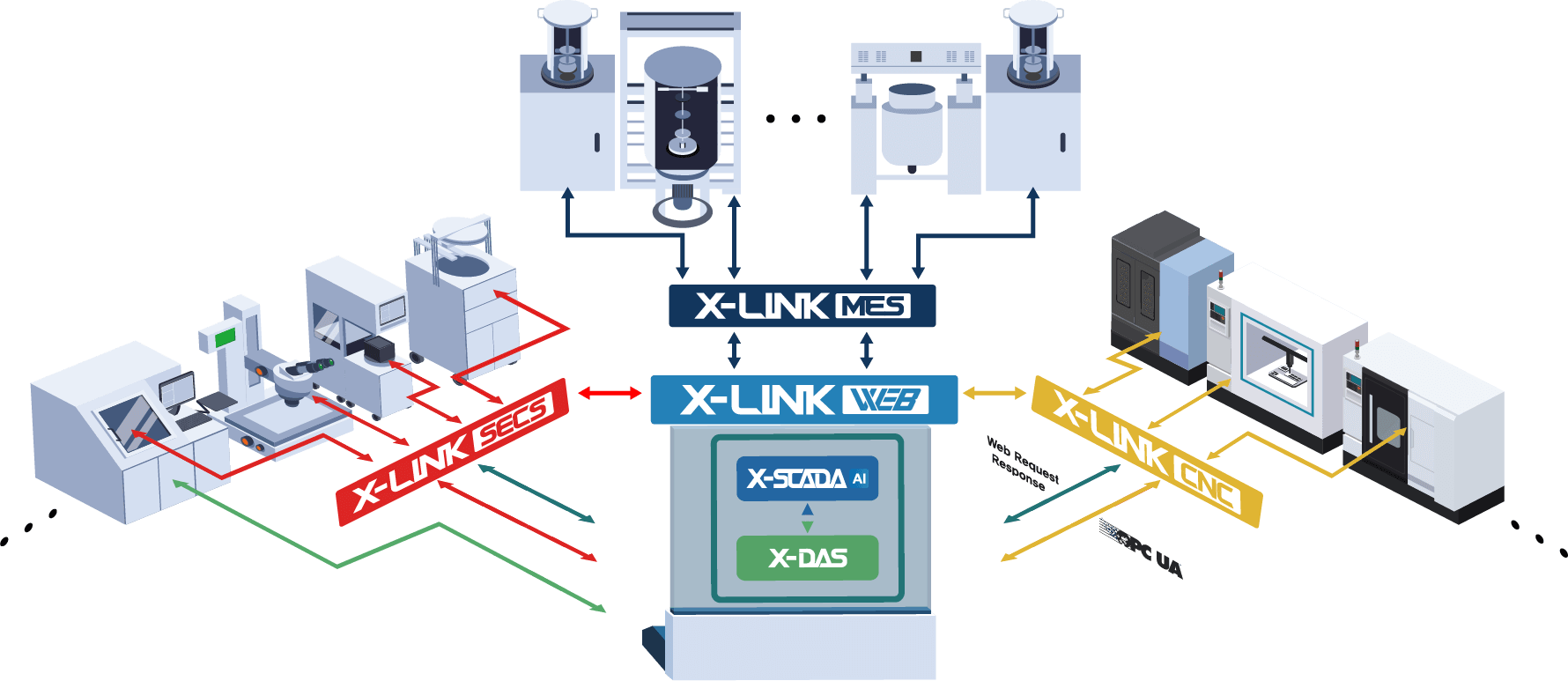

X-LINK Family

Customized middleware specialized for various semiconductor facilities and process lines

This is a high-performance middleware that supports seamless communication between semiconductor manufacturing equipment and management systems. The user can configure SECS messages for equipment condition monitoring, control, process management, and data collection through message settings. The user can configure scenarios that the users want, such as script execution, log recording, and external program execution, based on the value of the message set through scenario settings, by clicking on the UI and using Drag & Drop. Additionally, simulation capabilities allow the user to test configured SECS messages and scenarios before deploying them on actual equipment, and visually verify the results.

Real-time data collection from sensors and controllers of CNC machines

This is a high-performance middleware for highly efficient equipment operation in smart manufacturing environments, real-time data-driven decision making, and productivity maximization. Based on high compatibility with various CNC controllers such as FANUC and Brother, it is designed to precisely collect and monitor key status information of machine tools in real time (absolute coordinates, load rate, RPM, voltage, load current, alarm status, processing time, and tool information, etc.). In addition, it adopts communication based on the OPC UA standard protocol to strengthen data integrity and security, and provides a high availability data interface to support flexible connection with heterogeneous systems.

Customized scenarios to manufacturing processes and facilities to build a smart manufacturing environment that is flexible to change

It is designed to efficiently perform process and facility management by communicating directly and indirectly with the facility, and provides various functions to enable real-time monitoring, facility control, data collection and analysis, and maintain an optimal production environment. In particular, by utilizing the No-Coding based scenario management function, the user can easily design and operate production activities of complex and precise processes without programming knowledge. This can effectively achieve various goals such as automated process operation, quality control, and productivity improvement. In addition, the solution can be flexibly applied in both on-premise and cloud environments, and its functions can be customized to meet the needs of the company, allowing it to be introduced in a form optimized for various manufacturing sites.

Integrated operation management of heterogeneous web applications based on SaaS

This is an advanced solution that fully supports the HTML5 standard and allows integrated operation of services operating in various Web Server and WAS (Web Application Server) environments into a single platform. This solution enables integrated control of process monitoring systems operating in multiple industrial sites through real-time web-based linking, which drastically reduces development costs and time required to build individual systems. It is also an integrated monitoring application that maximizes interconnectivity between distributed services to enable efficient data flow management, web-based real-time monitoring, and highly scalable platform operation.

Key Featuers of X-LINK

X-LINK SECS

|

Control and operation through codeless scenario configuration |

|

Stable data transmission and event/alarm handling |

|

Configuration using Drag & Drop method |

|

Integration with X-SCADA for visualization |

|

Support for OPC UA communication and numerous PLCs |

|

Flexible scalability |

|

Big data solution-based(20,000 records per second per collection device) |

X-LINK CNC

|

Stable data collection through communication with CNC controllers |

|

Monitoring of general equipment functions |

|

Quality management based on collected data |

|

Easy data storage and management |

|

Monitoring of tool status within equipment |

|

Data storage in various databases |

X-LINK MES

|

Data collection and control through direct communication with various equipment |

|

Easy module management and operation |

|

Real-time monitoring of various information and equipment |

|

Process control and operation through simple clicks |

|

Lightweight modules |

|

Simplified management of complex processes |

X-LINK WEB

|

Data collection and control through direct communication with various equipment |

|

Easy module management and operation |

|

Monitoring various information and facilities in real time |

|

Process control and operation via clicks |

|

Lightweight module |

|

Manage complex processes concisely and simply |

With X-LINK,

With X-LINK, flexible production process operations are possible.

flexible production process operations are possible.

Rejection of unauthorized collection of e-mail addresses

This website prohibits unauthorized collection of posted e-mail addresses using e-mail collection programs or other technical devices. Violation of this may be punished by the Act on Promotion of Information and Communication Network Utilization and Information Protection, etc.

arrow_drop_down

arrow_drop_down

EN

EN

JP

JP